Thanks to its commitment to environmental protection, Raffmetal was among the first Italian companies in the aluminium sector to achieve the prestigious ISO 14001 environmental certification, obtained in 2004 for all production units.

In 2017, the company further strengthened its commitment by obtaining ISO 50001 certification, ensuring a systematic and continuous approach to improving energy performance.

HEAT RECOVERY PLANT

Since 2014, Raffmetal has invested in a heat recovery plant, a technology capable of capturing otherwise unused thermal energy and making it available and useful where needed.

These heat recovery systems deliver multiple benefits, including energy savings, lower energy costs and a reduction in environmental impact and CO₂ emissions.

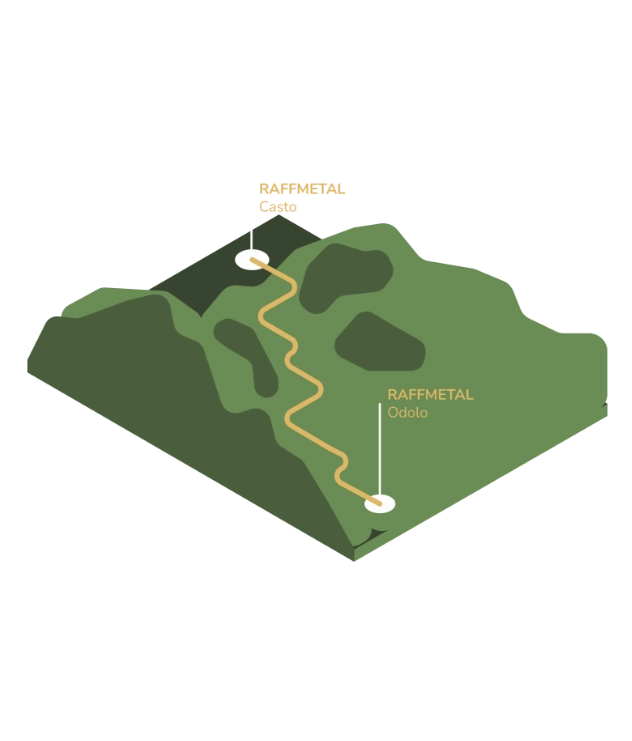

OXYGEN PIPELINE

Built in 2013, a pipeline of over 9 km connecting the Raffmetal plant to the Air Liquide network, resulting in a reduction of public-road traffic by more than 2,500 tanker trucks per year.

SALT SLAG RECOVERY

Since 1989, salt slag residues from melting have been recycled through a recovery plant, enabling the valorisation and recovery of chemical components: salt, granules and aluminium are reintroduced into Raffmetal’s cycle, while aluminium oxides are returned to the market and sold as the RAPAL product.

Since 1989, Raffmetal has not sent melting process residues to landfill.

GREEN ENERGY

Despite significant price fluctuations and the resulting ongoing uncertainty, Raffmetal has invested in the self-generation of green electricity through:

- the installation of photovoltaic panels on the roofs of its facilities,

- the installation of a steam turbine for thermal energy recovery.

BE THE CHANGE.

LOW CARBON ALUMINIUM FOR A SUSTAINABLE FUTURE