Raffmetal stands out for its stringent radiometric control, ensuring the total absence of radioactive traces in the material through repeated checks—from incoming raw material through to delivery of the finished product to the customer.

This commitment to safety and quality is essential to ensure compliance of the alloy produced and to safeguard the safety of the downstream aluminium value chain.

Raffmetal adopts state-of-the-art production techniques supported by highly effective metal cleaning treatments. In addition, gas levels—particularly hydrogen—are continuously monitored through alloy density measurements combined with micrographic examinations, maintaining high product cleanliness standards.

RAFFMETAL QUALITY

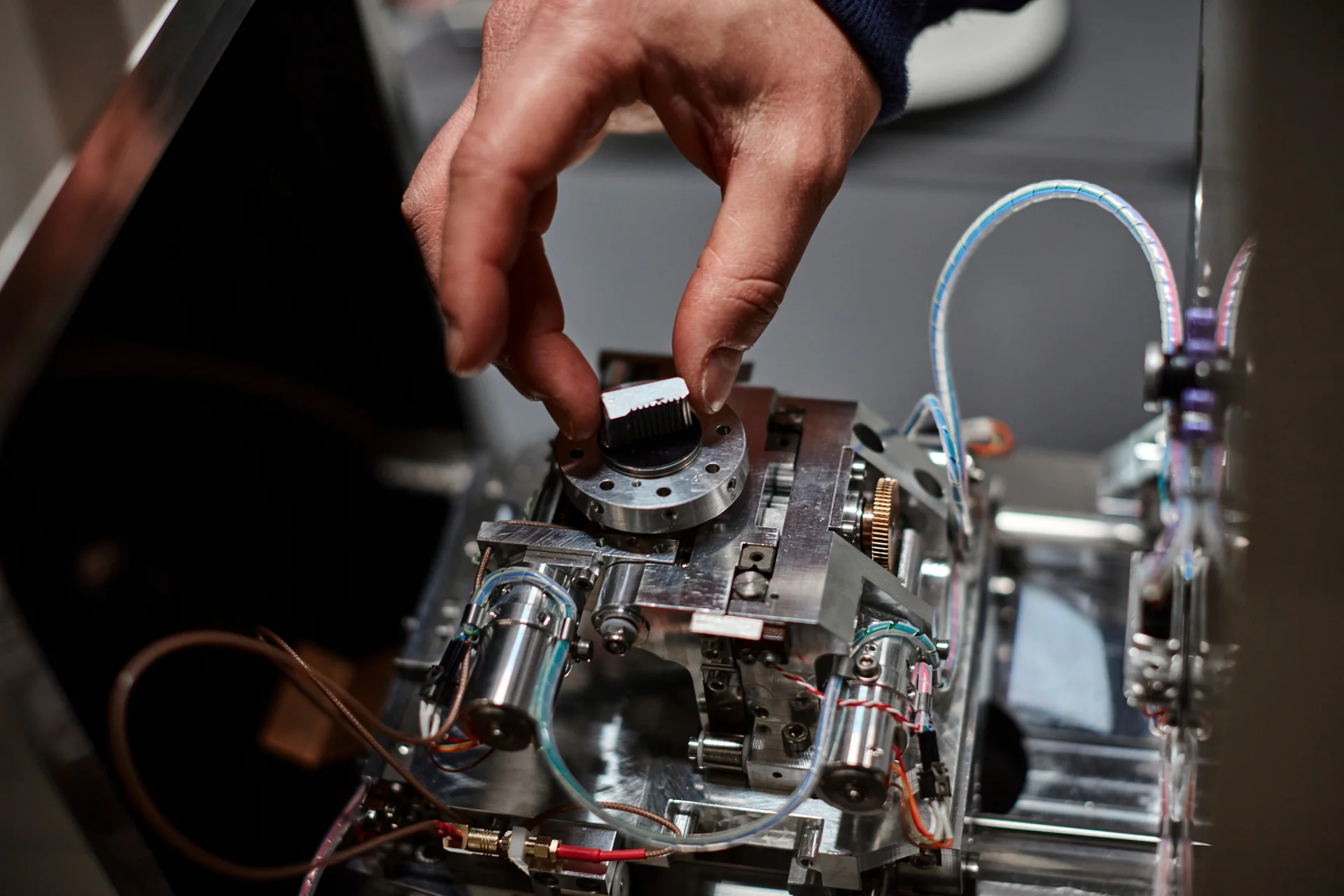

Raffmetal’s in-house laboratories, equipped with the most advanced instruments for aluminium control, rigorously analyse every stage of the production process.

The technology fleet includes multiple spectrometers capable of analysing dozens of chemical elements down to parts-per-million (ppm) levels. This process prevents the presence of trace elements that could compromise casting operations at foundries and reduce the performance of the finished product.

Raffmetal’s guarantee

High-precision micrographic analysis

The in-house metallurgical laboratory and dedicated technical team use state-of-the-art microanalysis technologies, such as optical and electron microscopes (SEM) with an EDS probe. This enables in-depth microanalytical assessments, ensuring our materials meet the highest expectations in terms of quality and performance.

BE THE CHANGE.

LOW CARBON ALUMINIUM FOR A SUSTAINABLE FUTURE