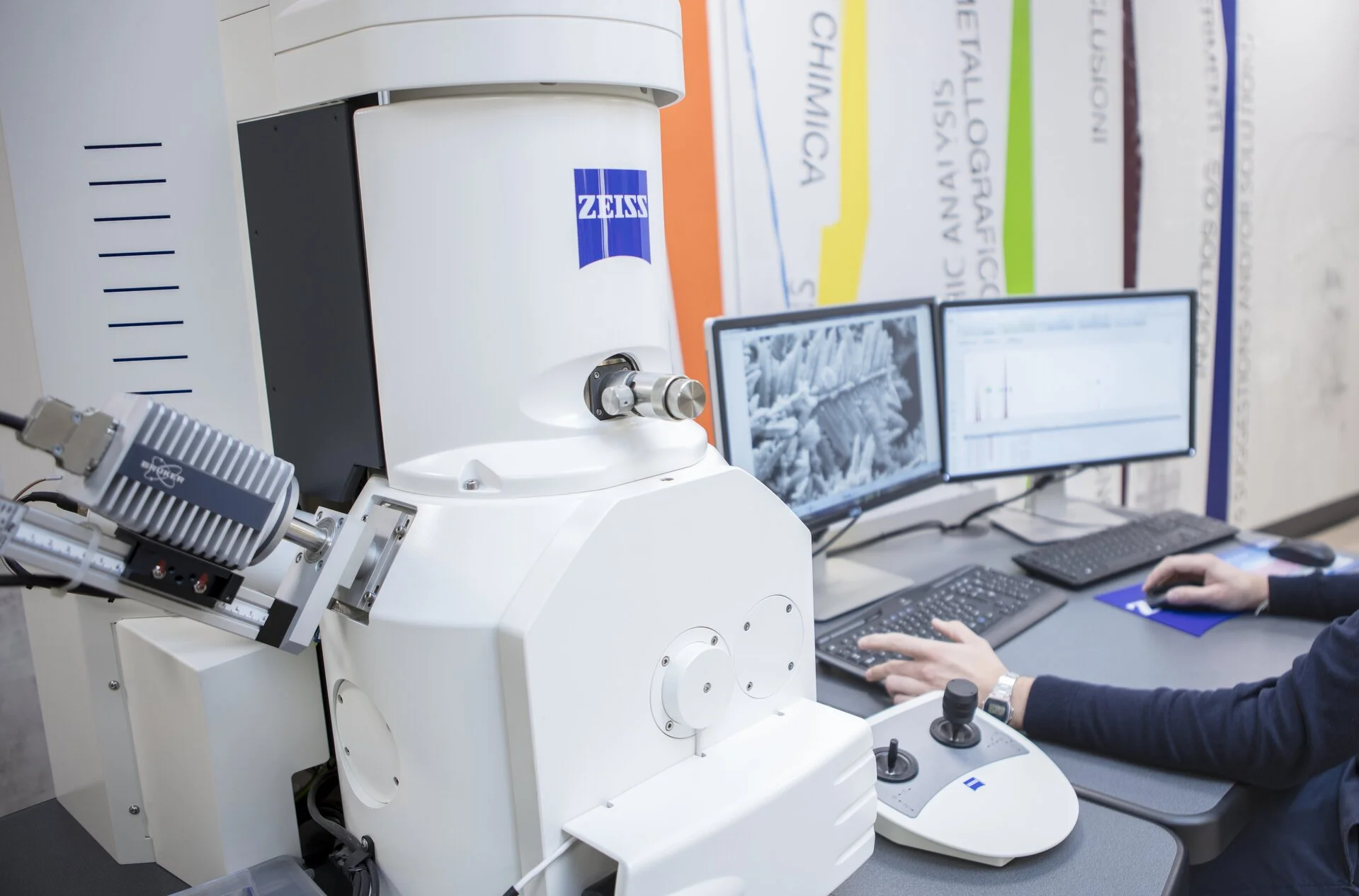

Raffmetal invests in advanced technologies to test and validate the potential of new alloys. Thanks to state-of-the-art tools and sophisticated analytical methods, the company can accurately assess the chemical and metallurgical characteristics of materials. In addition, through collaboration with customers and research centres, Raffmetal collects data on the mechanical properties of the alloys developed.

RAFFMETAL R&D

Research and Development are Raffmetal’s driving force, with a constant focus on innovation and on maintaining high quality performance.

The company relies on a team of experts, in collaboration with leading Universities and Research Centres, to valorise every type of scrap and develop alloys with improved mechanical and chemical properties.

The in-house laboratories, equipped with advanced instrumentation, support the day-to-day activities of the R&D team.

Advanced technologies

Customer care

Raffmetal’s customer care service goes beyond traditional support, extending upstream through a circular approach and offering a complete experience that guides customers from alloy purchase to finished product manufacturing—enhanced by technical sustainability consultancy.

Raffmetal’s technical support provides solutions to optimise alloy use, reduce energy consumption, minimise scrap and control costs. In addition, for selected premium partners, chemical and metallographic analyses and metal cleanliness tests are available.

Technical consultancy

Raffmetal’s low carbon footprint team, led by the Technical and Environmental Management, provides consultancy on quality, sustainability and circular economy to partners.

This continuously growing service supports partners in meeting regulations and market requirements, contributing to the achievement of sustainability goals.

Raffmetal develops competitive low-carbon-footprint products, EPD Certified, to support customers and suppliers on their sustainability journey.

PARTICIPATION IN MAJOR EUROPEAN PROJECTS

In an increasingly competitive economic landscape, participation in major European projects represents a strategic opportunity and a driver of continuous improvement. Raffmetal not only expands its knowledge and capabilities, but also promotes a collaborative approach that encourages the sharing of best practices and sector innovation.

Raffmetal is one of the 28 partners in the ZEvRA project, funded by Horizon Europe, which targets zero CO2 emissions for light electric vehicles (EVs) by 2035. ZEvRA will transform the EV value chain—from production to end-of-life processes—with a strong focus on sustainability.

Launched in January 2024 and running through December 2026, the project will validate Design for Circularity (DfC) methodologies for more than 84% of materials, such as metals and plastics. Training programmes for the automotive sector and awareness-raising initiatives on zero-emission solutions are also planned.

By collaborating with major manufacturers, ZEvRA aims to transform the lifecycle of at least 59% of electric vehicles in Europe by 2035.

European and national public institutions recognise both the economic importance and the supply risk of Critical Raw Materials (CRMs), which are essential to European competitiveness yet often subject to high risk due to concentration in a limited number of countries.

Raffmetal, leveraging the expertise developed in scrap selection and processing, was selected to participate in the SALEMA project, launched in 2021 and concluded in the first months of 2024. The main objective was to demonstrate the feasibility of a shift in the materials used to produce high-performance aluminium alloys.

SALEMA engaged the entire aluminium automotive sector to prove that the measures adopted are competitive and technically feasible, contributing to circular economy strategies.

The SALEMA project highlights how new challenges can stimulate innovation in the circular economy applied to aluminium, with potential benefits not only for the automotive industry but also for other sectors such as aviation, rail transport, packaging and construction. In this way, the development of low-carbon technologies is accelerated, delivering both economic and environmental benefits.

BE THE CHANGE.

LOW CARBON ALUMINIUM FOR A SUSTAINABLE FUTURE